jb capacitors company: from concept to finished product

Key words: jb capacitor, film capacitor, X2 capacitor,good quality, competitive price, SMD Aluminum Electrolytic Capacitors , Aluminum Electrolytic Capacitors , Plastic Film Capacitors,Metallized polypropylene capacitors,Metallized polyester capacitors

jb capacitors company is the recognized leader in film capacitor design and manufacture. Our innovative capacitor design capability offers the flexibility to meet your most demanding film capacitor requirement. As a professional capacitor manufacturer, we offer good quality and competitive price, as well as a diverse spectrum of standard product lines ranging from small chip size capacitors to large building blocks.

Electronic Concepts is extremely flexible with the ability to produce dielectric, produce stamped or machined terminals, fabricate enclosures in plastic or metals, perform unique testing and develop and build it’s own production and testing equipment. No matter how challenging your capacitor requirements, jb unique capabilities and expertise offer you film capacitor innovation without limits.

Most Strong Film Capacitors:

1. JFB--Metallized Polyester Film Capacitors

2. JFD--Box Metallized Polyester Film Capacitors

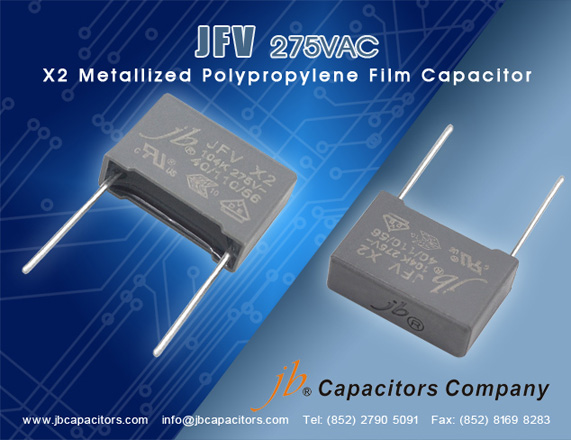

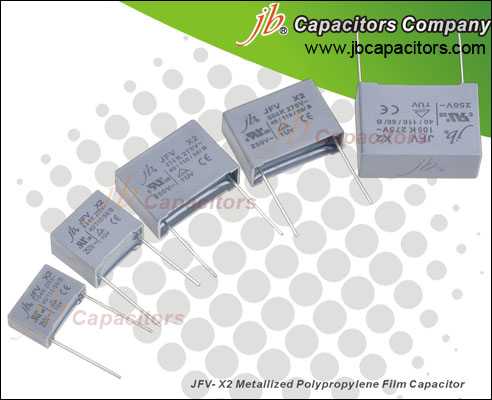

3. JFV--X2 Met Polypropylene Film Capacitors ( focus on 275VAC, widely used for power supply, lighting, white goods and home appliance)

4. JFP--High Voltage Met Polypropylene Film Capacitors. (1000V, 1600V, 2000V, 2500V)

5. JFQ--Double Sided Box Met Polypropylene Film Capacitors. ( Cross Wima FKP1, MKP10, Vishay MKP383, MKP1840, Kemet R76)

6. JFX--Premim Met Polypropylene Film Capacitors, Axial lead ( Also called audio film capacitors, specially used for high end Amplifier, Cross over and Speakers)

Aluminum Electrolytic Capacitors:

1. SMD Aluminum Electrolytic Capacitors. standard, General purpose.

2. Snap in Electrolytic Capacitors, 2pins, 4pins.

3. Screw Terminals Electrolytic Capacitors, with and without stud. (used for power supply, welding machine, store energy.)

Welcome to contact with us via info@jbcapacitors.hk when you need help!