2011-8-5 15:3:2

views

jb capacitors company is very strong on Aluminum electrolytic capacitors, including snap-in, screw type and lug type.

Snap-in Aluminum Electrolytic Capacitors is widely used on power supply. If the end product is industrial motor, some customer may requires to add a mica sheet of plastic layer or other non-flammable material between the Aluminum electrolytic body and PCB. As we know, the motor has vibrations, and it keeps running 24 hours, so that the capacitor will be very hot. The piece of plastic layer is used as insulation to prevent the capacitor from shorting itself.

2011-8-3 16:0:51

views

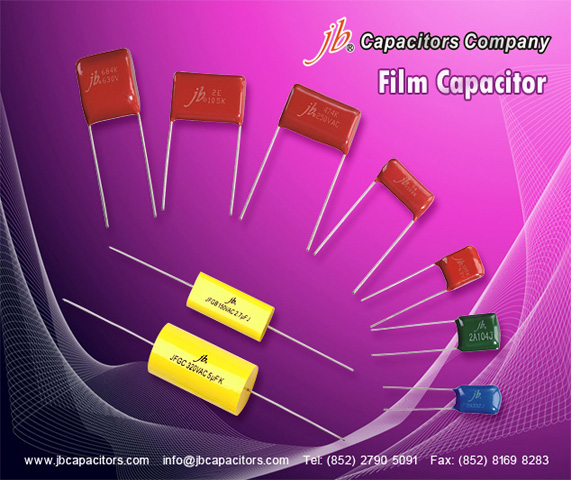

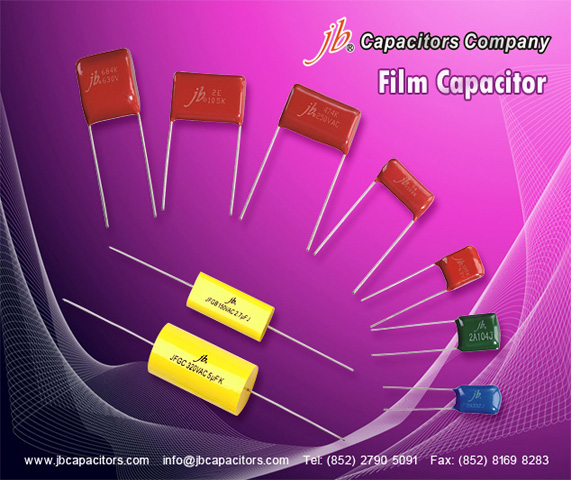

Motor Start Metallized Polyproyplene Film Capacitors ( Motor Run capacitors ) , in China, also called CBB60, CBB61, CBB65.

jb Capacitors Company produce 18 kinds of motor starting capacitors, with different terminals.

Tony: I heard that Brand Electronicon discontinued E23 series motor starting film capacitors since last year.

Peter: Really ? how about Iskra motor starting capacitors ?

Terry : I bought Iskra capacitors, but their prices are too high.

Anna: I used to use Iskra brand, but now I use jb Capacitors Brand, quality is very good, and their prices are very reasonable.

I buy from jbcapacitors JFS--17 series for many years.

Piotry: Yes, really good brand, I buy jb capacitors JFS-13 series for a long time, their delivery time is very fast too.

I am going to buy their JFS--6 series soon. The box type with terminals motor run capacitors are also very popular.

I also received information from jb capacitors, seems their JFS-17 can replace Electronicon E23 series.

Tony: Sounds great !! I will contact with jb capacitors and check soon.

2011-8-1 15:49:43

views

jb capacitors company not only produce MKT MKP Film capacitors, also produce high quality Screw

terminals Aluminum Electrolytic capacitors, some people called Large can aluminum electrolytic capacitors, I.E. Snap-in, Screw, Lug type. Long load life, high ripple current...

Recently jb strongly recommend screw type aluminum electrolytic capacitors, with very high quality, widely use in power supply, UPS, Welding Machines, filter etc...

See below our strong series:

JMJ--Screw terminal aluminum electrolytic capacitors, 2000hours at 85C'---cross: Epcos B41456,B41458/ B43456,B43458/ B43564, B43584/ B43455, B43457 CDE: CGS series

JML--Screw terminal aluminum electrolytic capacitors, 2000hours at 105C'--Cross:

Epcos B43740,B43760/B41560,B41580/ B43450,B43770(high ripple current)

JMN--Screw terminal aluminum electrolytic capacitors, 5000hours at 85C'

JMQ--Screw terminal aluminum electrolytic capacitors, 5000hours at 105C'

2011-7-29 15:36:24

views

jb capacitors company is very strong on Aluminum electrolytic capacitors, including snap-in, screw type and lug type.

Snap-in Aluminum Electrolytic Capacitors is widely used on power supply. If the end product is industrial motor, some customer may requires to add a mica sheet of plastic layer or other non-flammable material between the Aluminum electrolytic body and PCB. As we know, the motor has vibrations, and it keeps running 24 hours, so that the capacitor will be very hot. The piece of plastic layer is used as insulation to prevent the capacitor from shorting itself.

2011-7-27 15:23:25

views

jb capacitors company strongly recommend:

JFQ-Box type double sided metallized polypropylene film capacitor

This type capacitors capacitance range is wide, voltage is up to 2000V, can cross to many high end European brands:

Capacitance Range: 0.00022uF ~ 3.9uF

Rated Voltage: 250V, 400V, 630V, 1000V, 1400/1600V, 2000V.DC

Lead Spacing: 7.5mm, 10mm, 15mm, 22.5mm, 27.5mm

Cross Reference:

Arcotronics(Kemet) : R76 series

EVOX RIFA: PHE450 series

Vishay: MMKP 383 Series

Wima: MKP 10,

Philkor: PCMP384 series etc...

Applications: electronic ballast, frenquency control, lighting etc...

2011-7-25 16:22:37

views

Polyester films, are clearer and a higher quality than lower grade films, which tend to be foggy. Premium films also endure extreme environments and severe stress conditions more favorably. Films with higher polyester content are more rigid and feel thicker than films with more adhesive content.

Polypropylene film is softer than polyester, but still has excellent clarity. These films have strong chemical resistence, good color stability over printed sheets, and good elasticity which allows the film to lay extremely flat. Due to its softness and flatness, polypropylene films are most often used in single-sided laminating.

2011-7-22 16:16:56

views

Symbol:T

Unit:(s)

When a capacitor discharges its charge throught a resistor, the charge of the capacitor decreases with time. The decreasing charge follows an exponential decay curve.

2011-7-20 11:17:29

views

A super capacitor is also known as a double-layer capacitor. It polarizes an electrolytic solution to store energy electro statically. Though it is an electrochemical device, no chemical reactions are involved in its energy storage mechanism. This mechanism is highly reversible, and allows the ultra capacitor to be charged and discharged hundreds of thousands of times.

A super capacitor can be viewed as two non reactive porous plates, or collectors, suspended within an electrolyte, with a voltage potential applied across the collectors. In an individual super capacitor cell, the applied potential on the positive electrode attracts the negative ions in the electrolyte, while the potential on the negative electrode attracts the positive ions. A dielectric separator between the two electrodes prevents the charge from moving between the two electrodes.

2011-7-18 11:8:46

views

A super capacitor is also known as a double-layer capacitor. It polarizes an electrolytic solution to store energy electro statically. Though it is an electrochemical device, no chemical reactions are involved in its energy storage mechanism. This mechanism is highly reversible, and allows the ultra capacitor to be charged and discharged hundreds of thousands of times.

A super capacitor can be viewed as two non reactive porous plates, or collectors, suspended within an electrolyte, with a voltage potential applied across the collectors. In an individual supercapacitor cell, the applied potential on the positive electrode attracts the negative ions in the electrolyte, while the potential on the negative electrode attracts the positive ions. A dielectric separator between the two electrodes prevents the charge from moving between the two electrodes.

2011-7-15 23:19:12

views

Tape and Reel is a process of packing surface mount devices (SMD's) by loading them into individual pockets comprising what is known as a pocket tape or carrier tape. The carrier tape is wound around a reel for convenient handling and transport. The reel is enclosed in a reel box before it is finally shipped to the customer.

A Tape-and-Reel holds hundreds-to-thousands of surface mount devices. This saves in labor and will further reduce manufacturing costs for automated circuit board assembly.

jb capacitors company manufactures and markets SMD Aluminum Electrolytic capacitors. They are both with tape-and-reel package.

JCS - 2000H at 85°C SMD Aluminum Electrolytic Capacitors

JCK- 1000H at 105°C SMD Aluminum Electrolytic Capacitors