2011-5-9 22:47:1

views

This capacitor is small, with long lifespan and good self-healing ability. It is widely used as the start-up and running capacitor, especially for micro water pumps, cleaning machines, washing machines, and single-phase water pump motors.

Features:

jb film capacitors offers a full voltage range, from 63VDC to 2000VDC; our high voltage film capacitors include JFP (epoxy coating dipped type) and JFQ (box type) two series. JFA mylar polyester film capacitors, 1000V, 1200V is very popular. Also AC voltage and DC voltage both available, AC type film capacitors include JFC (AC metallized polyester film capacitors), JFN & JFO X2 class and JFT X1 class......

Tolerance range: ±1%, ±2%, ±2.5%, ±5%, ±10%

Temperature range: normally film capacitors temperature range is -40'C to 85'C, for some series we can provide a wide temperature range up to 125'C.

jb film capacitors technology available: winding technology and stacked technology (JFJ mini box series); single side metallized structure and double sided metallized structure (JFQ series) Safety Approvals of film capacitors: UL, TUV, CE, VDE...., X2 class, X1 class

Packaging: Ammo packaging and Bulk packaging both available, and all jb film capacitors are RoHS compliant

2011-5-6 13:37:20

views

For reflow, use thermal conduction systems such as infrared radiation (IR) or hot blast. Vapor heat

transfer systems (VPS) are not recommended.

Observe proper soldering conditions (temperature, time, etc.).

Do not exceed the specified limits.

Temperature measuring method: Measure temperature in assuming quantitative production, by sticking the thermo-couple to the capacitor upper part with epoxy adhesives.

Consult us for additional reflow restrictions.

2011-5-4 23:4:35

views

For reflow, use thermal conduction systems such as infrared radiation (IR) or hot blast. Vapor heat transfer systems (VPS) are not recommended.

Observe proper soldering conditions (temperature, time, etc.).

Do not exceed the specified limits.

Temperature measuring method: Measure temperature in assuming quantitative production, by sticking the thermo-couple to the capacitor upper part with epoxy adhesives.

Consult us for additional reflow restrictions.

2011-5-2 22:48:36

views

jb Aluminum Electrolytic Capacitor - JNE

Features

- Load life of 2000 hours at 105°C

- High ripple current

- Smaller size

- PCB Mounting

Construction

- Charge/discharge-proof, polar

- Aluminum case, fully insulated with PVC

- Version with PET insulation available

- Version with additional PET insulation cap on terminal side

- available for insulating the capacitor from the PCB

- Snap-in solder pins to hold component in place on PC-board

- Minus pole marking on case surface

- Minus pole not insulated from case

- Overload protection by safety vent on the base

2011-4-29 10:17:53

views

In theory, capacitors can be coupled both in series and parallel. If you need a 100MF cap and have two at 50MF, you can connect them in parallel, and that will give you 100MF (and same voltage rating as each). If you couple them in series, you get half the capacitance, and double voltage rating. But coupling electrolytic capacitors in series to get higher voltage rating must generally be discouraged. For this to work, you must be sure that the two (or more) caps share the voltage load properly; a resistor network can augment this, but if leakage currents are markedly different or the capacitors age differently, you are looking at a potential disaster, so do this only as a last resort, if at all.

2011-4-26 22:4:41

views

As already mentioned, never go below the voltage rating of the original part. Standards in voltage ratings have changed over the years, so you may not be able to find an exact replacement for the 250V capacitor you want to replace. Instead use 270V or even more. The only adverse effects of using a too high rating is price and, maybe, physical size; small problems compared to the risk of a capacitor impersonating a large firecracker inside your equipment!

Same is true of capacitance values: Standards have changed, and instead of old values like 15MF, 32MF, 50MF, etc, you will find 16, 33, 67, and such. The capacitance values of electrolytic capacitors are normally not very critical to the circuitry function, especially not in filters. A good rule of thumb is to go for the range between -20% to +100% of the original value, of course choosing a value as close as you can get.

There is a caveat here: If those capacitors have already been changed once, the values you look at may already deviate from the original values. If a 260V 40MF capacitor has sometime along the route been replaced with a 450V 67MF, you could be heading for problems; a 650V 100MF replacement will probably work, but we are getting out of bounds (oversize filter caps put extra strain on rectifier tubes, not to mention the price). So it would be nice to make a rough calculation to see if the value we are aiming for is reasonable.

2011-4-25 16:9:57

views

Aluminum electrolytic capacitors have a bi-polar structure. This is marked on the body of the capacitor. A capacitor must not be mounted with reversed polarity. The application of an AC or reverse voltage may cause a short circuit or damage the capacitor. Bi-polar capacitors must not be used in AC applications, where the polarity may be reversed in the circuits or is unknown.

jb SMD Aluminum Electrolytic Capacitor Product List

JCS - 2000H at 85°C SMD Aluminum Electrolytic Capacitor

JCK - 1000H at 105°C SMD Aluminum Electrolytic Capacitor

SMD aluminum electrolytic capacitors, jb Capacitors provides the most common series: 2000h at 85°C SMD aluminum electrolytic capacitors and 1000h at 105°C SMD aluminum electrolytic capacitors. jb Capacitors sell very competitive prices and our monthly output for SMD aluminum electrolytic capacitors can reach 30 millions units.

2011-4-22 16:4:8

views

The typical temperature range for aluminum electrolytic capacitors is –40 °C to 85 °C or 105 °C. Capacitance varies about +5% –40% over the range with the capacitance loss all at cold temperatures. Capacitors rated –55 °C generally only have –10 % to –20 % capacitance loss at –40 °C. Cold temperature performance for rated voltages of 300 V and higher is often worse, and temperature performance varies by manufacturer.

2011-4-20 15:55:3

views

Aluminum Electrolytic Capacitors capacitor element is wound on a winding machine with spindles for one-to-four separator papers, the anode foil, another set of one-to-four separator papers and the cathode foil. These are wound into a cylinder and wrapped with a strip of pressure-sensitive tape to prevent unwinding. The separators prevent the foils from touching and shorting, and the separators later hold the reservoir of electrolyte.

Before or during winding aluminum tabs are attached to the foils for later connection to the capacitor terminals. The best method is by cold-welding of the tabs to the foils with tab locations microprocessor controlled during winding so that the capacitor element’s inductance can be less than 2 nH. The older method of attachment is by staking, a process of punching the tab through the foil and folding down the punched metal. Cold welding reduces short-circuit failures and performs better in high-ripple current and discharge applications in which the individual stakes may fail from high current like buttons popping off one at a time from a fat-man’s vest.

2011-4-19 11:55:32

views

Aluminum Electrolytic Capacitor are connected in series, back-to-back with the positive terminals or the negative terminals connected, the resulting single capacitor is a non-polar capacitor with half the capacitance. The two capacitors rectify the applied voltage and act as if they had been bypassed by diodes. When voltage is applied, the correct-polarity capacitor gets the full voltage. In non-polar aluminum electrolytic capacitors and motor-start aluminum electrolytic capacitors a second anode foil substitutes for the cathode foil to achieve a non-polar capacitor in a single case.

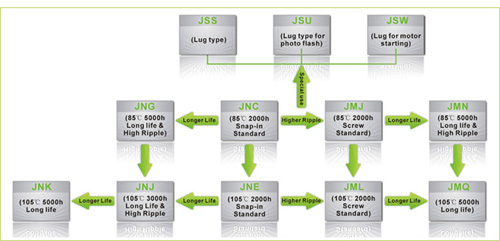

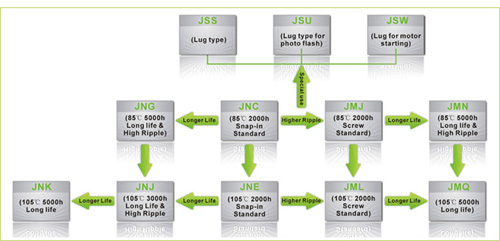

jb Capacitors markets Aluminum Electrolytic Capacitors, including JNC, JNE ,JNG ,JNJ , JNK , JMJ ……The following Picture shows our Aluminum Electrolytic Capacitors. For the detailed information ,We introduced in our website www.jbcapacitors.com .If necessary, you can contact our sales directly. I am sure you can get your satisfaction.