jb Popular Aluminum Electrolytic Capacitors

jb Capacitors manufactures and markets Aluminum Electrolytic Capacitors, including Snap-in Type Aluminum Electrolytic Capacitors, Screw Type Aluminum Electrolytic Capacitors, Lug Type Aluminum Electrolytic Capacitors and Radial Aluminum Electrolytic Capacitors.

We are a professional manufacturer for aluminum electrolytic capacitors. We have around 40 years manufacturing experience of electrolytic capacitors.

Generally speaking, jb Capacitors focuses on large can aluminum electrolytic capacitors and SMD aluminum electrolytic capacitors.

Large can aluminum electrolytic capacitors include snap in electrolytic capacitor, screw electrolytic capacitors and lug aluminum electrolytic capacitors.

Let’s introduce our Aluminum Electrolytic Capacitors today. We have some fields about Aluminum Electrolytic Capacitors.

Below is our strong series. If you cannot find the suitable products below, please feel free to mail us.

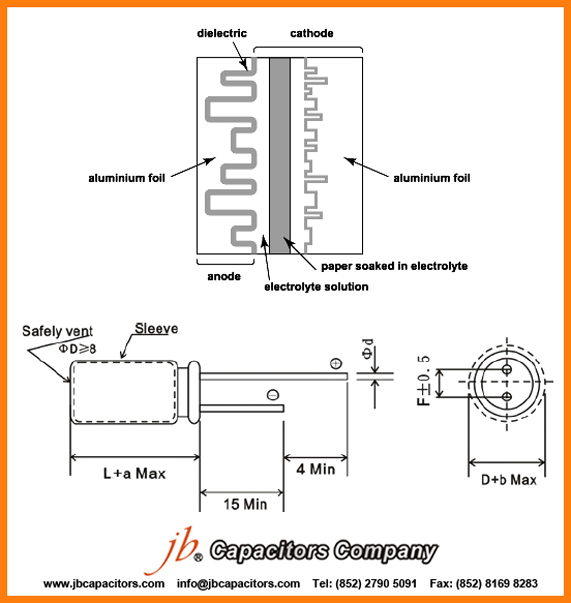

Radial Aluminum Electrolytic Capacitors

JRA - 2000H at 85°C, Radial Aluminum Electrolytic Capacitors

JRB - 2000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRC - 2000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRD - 5000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRG - Long Life at 105°C, Radial Aluminum Electrolytic Capacitors

JRJ - 1000H at 85°C, Radial Aluminum Electrolytic Capacitors,7mm Height

JRK - 20000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRW - 20000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRQ - 1000H at 105°C, Bi-Polarized Radial Aluminum Electrolytic Capacitors

Axial aluminum electrolytic capacitors

JAA - 2000H at 85°C, Low Leakage Current, Axial aluminum electrolytic capacitors

JAB - 2000H at 85°C, Low Voltage, Axial aluminum electrolytic capacitors

JAH - 1000H at 105°C, Low Voltage, Axial aluminum electrolytic capacitors

JAC - 1000H at 105°C, DF at Max 4% BP Axial Aluminum Electrolytic Capacitors for Audio System

JAD - 1000H at 105°C, DF at Max 5% BP Axial Aluminum Electrolytic Capacitors for Audio System

JAE - 1000H at 105°C, DF at Max 10% BP Axial Aluminum Electrolytic Capacitors for Audio System

JAF - 1000H at 105°C, DF at Max 10% BP Axial Aluminum Electrolytic Capacitors for Audio System

Snap in aluminum electrolytic capacitors

JNC - 2000H at 85°C, Snap in Aluminum Electrolytic Capacitor, for Speaker Network

JNE - 2000H at 105°C, Miniaturized, Snap in Aluminum Electrolytic Capacitor

JNG - 5000H at 85°C, Snap in Aluminum Electrolytic Capacitor, Miniaturized Size, Long Life

JNJ - 3000H at 105°C, Miniaturized, Long Life Snap in Aluminum Electrolytic Capacitor

JNK - 5000H at 105°C Snap in Aluminum Electrolytic Capacitor

Screw type aluminum electrolytic capacitors

JMJ - 2000H at 85°C, Miniaturized, Screw Aluminum Electrolytic Capacitor

JML - 2000H at 105°C Screw Aluminum Electrolytic Capacitor

JMN - 5000H at 85°C Screw Aluminum Electrolytic Capacitor, long time

JMQ - 5000H at 105°C Screw Aluminum Electrolytic Capacitor, for Inverter

Lug Aluminum Electrolytic Capacitors

JSS - 85°C, Miniaturized Size, Lug Aluminum Electrolytic Capacitor

JSU - Photo Flash, Lug Aluminum Electrolytic Capacitor

JSW - Motor Starting Capacitor