jb reminder-Please send us capacitor inquiry before Summer holiday

Hi, Dear Sir.

When will your summer holiday start? are you looking forward to it now?

Do you have some inquiry before your summer holiday? We can make sure offer high quality, best price, short delivery time.

Our Hot Seller and Strong items as below:

★JFB--Metallized Polyester Film Capacitor (CL21, MTK series)

★JFL--Metallized Polypropylene Film Capacitor (CBB21, MKP series)

★JFP--High Voltage Metallized Polypropylene Film Capacitor (CBB81 series)

★JFW--X2 Metallized Polypropylene Film Capacitor with VDE, ENEC and UL approvals.

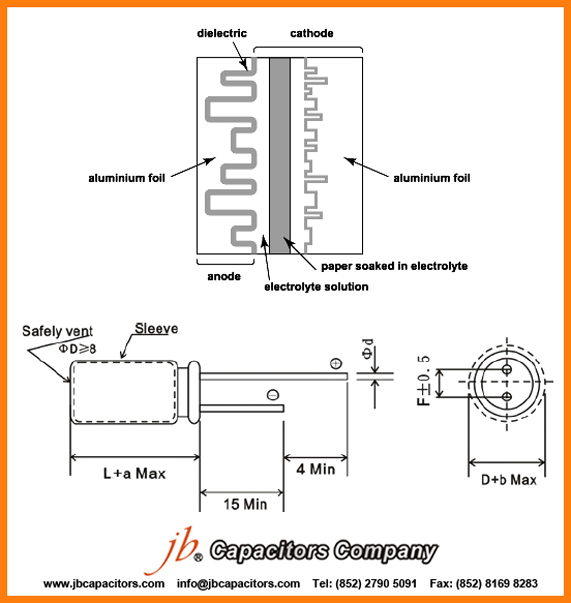

★JRA/JRB--Radial Aluminum Electrolytic capacitor 2000H at 85C, 2000H at 105C

★JYA/JYC—Radial Ceramic capacitor

★JYT/JYS--SMD Ceramic capacitor

★JCS/JCK—SMD Aluminum electrolytic capacitor

Wait for your early opportunity.