jb ISO Qualified Factory

Are you looking for an ISO-qualified factory to reduce your capacitor business costs?

Or have you purchased from large brands like Epcos, Vishay, Kemet, or Arcotronics? Feel free to send us their part numbers for cross-referencing.

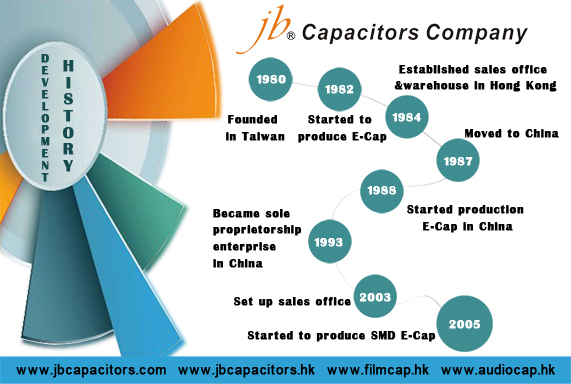

Here is a summary of our company profile. For more details, please check the PDF link below:

Company Profile PDF

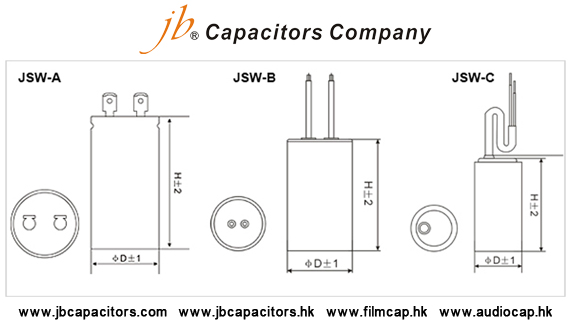

- Two factories offering a full range of MKT, MKP Capacitors, JFV X2 MKP Film Capacitors, and SMD Electrolytic Capacitors

- Certifications: ISO 9001:2008, RoHS, SGS, ENEC, VDE, UL

- Cross-references to major brands: Epcos, Vishay, Kemet, Pilkor, Wima, Panasonic, Nichicon, and Chemicon

- Trade references: Leading global companies across various industries

- Exhibitions: Electronica Asia, Electronica Munich, Expo Electronica, FIEE

- High quality, competitive prices, laser marking, and excellent packaging

- Professional engineering and sales support

We look forward to your reply and inquiry. Thank you!

.jpg)