2011-7-15 23:19:12

views

Tape and Reel is a process of packing surface mount devices (SMD's) by loading them into individual pockets comprising what is known as a pocket tape or carrier tape. The carrier tape is wound around a reel for convenient handling and transport. The reel is enclosed in a reel box before it is finally shipped to the customer.

A Tape-and-Reel holds hundreds-to-thousands of surface mount devices. This saves in labor and will further reduce manufacturing costs for automated circuit board assembly.

jb capacitors company manufactures and markets SMD Aluminum Electrolytic capacitors. They are both with tape-and-reel package.

JCS - 2000H at 85°C SMD Aluminum Electrolytic Capacitors

JCK- 1000H at 105°C SMD Aluminum Electrolytic Capacitors

2011-6-27 15:20:51

views

JMQ is one of our screw type aluminium electrolytic capaciotrs. it can be used in electrical source panel.

And one of the panel function is that it can control pulse current discharge in plasma generator device.

Pls. click the link for the specification.

http://www.jbcapacitors.com/pdf/JMQ-5000H-at-105-Screw-Aluminum-Electrolytic-Capacitor.pdf

2011-6-3 12:57:2

views

Aluminum is used for the electrodes by using a thin oxidization membrane. Large values of capacitance can be obtained in comparison with the size of the capacitor, because the dielectric used is very thin. The most important characteristic of electrolytic capacitors is that they have polarity. They have a positive and a negative electrode.[Polarised] This means that it is very important which way round they are connected. If the capacitor is subjected to voltage exceeding its working voltage, or if it is connected with incorrect polarity, it may burst. It is extremely dangerous, because it can quite literally explode. Make absolutely no mistakes.

Generally, in the circuit diagram, the positive side is indicated by a "+" (plus) symbol.

Electrolytic capacitors range in value from about 1µF to thousands of µF. mainly this type of capacitor is used as a ripple filter in a power supply circuit, or as a filter to bypass low frequency signals, etc. Because this type of capacitor is comparatively similar to the nature of a coil in construction, it isn't possible to use for high-frequency circuits. (It is said that the frequency characteristic is bad.)

2011-5-25 17:2:32

views

The aluminum foil that makes up the plates in the electrolytic capacitor is treated in a few different processes to make it work properly and more efficiently. The most important process is the anodizing of the foil. Anodizing is a process that forms a very thin layer of aluminum oxide on one or both sides of the foil when the foil is immersed in an acidic solution and direct current is applied to the foil (one lead of the DC power supply is connected to the foil and the other is connected to a conductive plate in the acidic solution). This layer of aluminum oxide is the dielectric (insulator) and serves to block the flow of direct current. To increase the surface area on the foil (and ultimately increase capacitance), the foil can be etched by a chemical process. This would be done before the anodizing.

2011-5-23 17:10:18

views

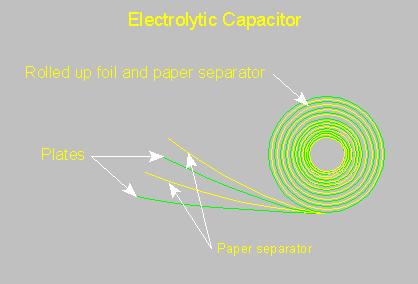

Electrolytic caps are more complex than film capacitors and are generally used for larger capacitance values (0.47 microfarad and higher). The electrolytic capacitor generally consists of 2 layers of aluminum foil with a layer of paper material between the plates. It looks a little like this:

2011-5-13 17:49:11

views

Here are precautions in using aluminum electrolytic capacitors at high altitudes, such as in

mountainous regions and in aircrafts.

As the altitude rises, the air pressure decreases. Therefore, if the capacitor is used at high altitudes, the atmospheric pressure becomes lower than the internal pressure of the capacitor. Due to the

construction of the aluminum electrolytic capacitor, there is no concern in using them at altitudes lower than about 10,000 (m).

2011-5-6 13:37:20

views

For reflow, use thermal conduction systems such as infrared radiation (IR) or hot blast. Vapor heat

transfer systems (VPS) are not recommended.

Observe proper soldering conditions (temperature, time, etc.).

Do not exceed the specified limits.

Temperature measuring method: Measure temperature in assuming quantitative production, by sticking the thermo-couple to the capacitor upper part with epoxy adhesives.

Consult us for additional reflow restrictions.

2011-5-2 22:48:36

views

jb Aluminum Electrolytic Capacitor - JNE

Features

- Load life of 2000 hours at 105°C

- High ripple current

- Smaller size

- PCB Mounting

Construction

- Charge/discharge-proof, polar

- Aluminum case, fully insulated with PVC

- Version with PET insulation available

- Version with additional PET insulation cap on terminal side

- available for insulating the capacitor from the PCB

- Snap-in solder pins to hold component in place on PC-board

- Minus pole marking on case surface

- Minus pole not insulated from case

- Overload protection by safety vent on the base

2011-4-26 22:4:41

views

As already mentioned, never go below the voltage rating of the original part. Standards in voltage ratings have changed over the years, so you may not be able to find an exact replacement for the 250V capacitor you want to replace. Instead use 270V or even more. The only adverse effects of using a too high rating is price and, maybe, physical size; small problems compared to the risk of a capacitor impersonating a large firecracker inside your equipment!

Same is true of capacitance values: Standards have changed, and instead of old values like 15MF, 32MF, 50MF, etc, you will find 16, 33, 67, and such. The capacitance values of electrolytic capacitors are normally not very critical to the circuitry function, especially not in filters. A good rule of thumb is to go for the range between -20% to +100% of the original value, of course choosing a value as close as you can get.

There is a caveat here: If those capacitors have already been changed once, the values you look at may already deviate from the original values. If a 260V 40MF capacitor has sometime along the route been replaced with a 450V 67MF, you could be heading for problems; a 650V 100MF replacement will probably work, but we are getting out of bounds (oversize filter caps put extra strain on rectifier tubes, not to mention the price). So it would be nice to make a rough calculation to see if the value we are aiming for is reasonable.

2011-4-22 16:4:8

views

The typical temperature range for aluminum electrolytic capacitors is –40 °C to 85 °C or 105 °C. Capacitance varies about +5% –40% over the range with the capacitance loss all at cold temperatures. Capacitors rated –55 °C generally only have –10 % to –20 % capacitance loss at –40 °C. Cold temperature performance for rated voltages of 300 V and higher is often worse, and temperature performance varies by manufacturer.