2011-4-4 10:36:22

views

Unlike many other types of capacitor, electrolytic capacitors are polarised and must be connected within a circuit so that they only see a voltage across them in a particular way. The capacitors themselves are marked so that polarity can easily be seen. In addition to this it is common for the can of the capacitor to be connected to the negative terminal.

It is absolutely necessary to ensure that any electrolytic capacitors are connected within a circuit with the correct polarity. A reverse bias voltage will cause the centre oxide layer forming the dielectric to be destroyed as a result of electrochemical reduction. If this occurs a short circuit will appear and excessive current can cause the capacitor to become very hot. If this occurs the component may leak the electrolyte, but under some circumstances they can explode. As this is not uncommon, it is very wise to take precautions and ensure the capacitor is fitted correctly, especially in applications where high current capability exists.

2011-4-2 10:32:15

views

Capacitor plague (also known as bad capacitors) is an ongoing problem with premature failure of large numbers of electrolytic capacitors of certain brands. Capacitors are used in various electronics equipment, particularly motherboards, video cards, compact fluorescent lamp ballasts, LCD monitors, and power supplies of personal computers. The first flawed capacitors were seen in 1999, but most of the affected capacitors were made in the early to mid 2000s. News of the failures (usually after a few years of use) forced most manufacturers to repair the defects and stop using the capacitors, but some bad capacitors were still being sold or used in equipment as of early 2007[update], and faults are still being reported as of 2011[update].Reference computer user reports on badcaps.net.

A serious quality control problem is that the issue only manifests after use over a period of time; poor quality electrolytic capacitors have the same measurable parameters as good ones when new. Only extensive accelerated life testing with high ripple currents and high operating temperatures can identify inferior components. After some normal use the bad capacitors fail predictably far sooner than normal end-of-life; most electronic components do not systematically fail in this way.

2011-4-1 11:45:12

views

The plates of an electrolytic capacitor are constructed from conducting Aluminum foil. As a result they can be made very thin and they are also flexible so that they can be packaged easily at the end of the production process. The two plates, or foils are slightly different. One is coated with an insulating oxide layer, and a paper spacer soaked in electrolyte is placed between them. The foil insulated by the oxide layer is the anode while the liquid electrolyte and the second foil act as cathode.

There are two geometries that are used for the connection leads or tags. One is to use axial leads, one coming from each circular face of the cylinder. The other alternative is to use two radial leads or tags, both of which come from the same face of the cylinder.

The lead styles give rise to the descriptions used for the overall capacitors. Descriptions of axial and radial will be seen in the component references.

2011-3-31 11:41:44

views

Capacitors have thin conducting plates (usually made of metal), separated by a layer of dielectric, then stacked or rolled to form a compact device.

Many types of capacitors are available commercially, with capacitance ranging from the picofarad, microfarad range to more than a farad, and voltage ratings up to hundreds of kilovolts. In general, the higher the capacitance and voltage rating, the larger the physical size of the capacitor and the higher the cost. Tolerances in capacitance value for discrete capacitors are usually specified as a percentage of the nominal value. Tolerances ranging from 50% (electrolytic types) to less than 1% are commonly available.

Another figure of merit for capacitors is stability with respect to time and temperature, sometimes called drift. Variable capacitors are generally less stable than fixed types.

2011-3-30 20:20:37

views

The breakdown voltage of the dielectric limits the power density of capacitors. For a particular dielectric, the breakdown voltage is proportional to the thickness of the dielectric.

If a manufacturer makes a new capacitor with the same dielectric as some old capacitor, but with half the thickness of the dielectric, the new capacitor has half the breakdown voltage of the old capacitor.

Because the plates are closer together, the manufacturer can put twice the parallel-plate area inside the new capacitor and still fit it in the same volume (capacitor size) as the old capacitor. Since the capacitance of a parallel-plate capacitor is given by:

this new capacitor has 4 times the capacitance as the old capacitor.

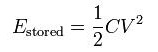

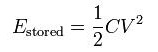

Since the energy stored in a capacitor is given by:

this new capacitor has the same maximum energy density as the old capacitor.

2011-3-29 20:16:53

views

Electrolytic capacitance values are not as tightly-specified as with bulk dielectric capacitors. Especially with aluminum electrolytic, it is quite common to see an electrolytic capacitor specified as having a "guaranteed minimum value" and no upper bound on its value. For most purposes (such as power supply filtering and signal coupling), this type of specification is acceptable.

jb Capacitors is a professional manufacturer for aluminum electrolytic capacitors. We have around 30 years manufacturing experience of electrolytic capacitors. Generally speaking, jb Capacitors focuses on large can aluminum electrolytic capacitors and SMD aluminum electrolytic capacitors. All these types of Aluminum Electrolytic Capacitors are detailed introduced in our website: www.jbcapacitors.com.

2011-3-28 19:44:32

views

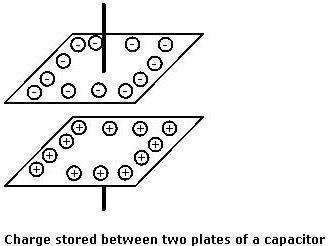

Capacitance is the ability to store electric charge. In its simplest form a capacitor consists of two parallel plates or electrodes that are separated from each other by an insulating dielectric. It is found that when a battery or any other voltage source is connected to the two plates as shown a current flows for a short time as it charges up. It is found that one plate of the capacitor receives an excess of electrons, while the other has too few. In this way the capacitor plate or electrode with the excess of electrons becomes negatively charged, while the capacitor electrode becomes positively charged.

2011-3-26 12:28:48

views

When using a capacitor, you must pay attention to the maximum voltage which can be used. This is the "breakdown voltage." The breakdown voltage depends on the kind of capacitor being used. You must be especially careful with electrolytic capacitors because the breakdown voltage is comparatively low. The breakdown voltage of electrolytic capacitors is displayed as Working Voltage.

The breakdown voltage is the voltage that when exceeded will cause the dielectric (insulator) inside the capacitor to break down and conduct. When this happens, the failure can be catastrophic.

2011-3-25 12:26:32

views

In aluminum electrolytic capacitors, the layer of insulating aluminum oxide on the surface of the aluminum plate acts as the dielectric, and it is the thinness of this layer that allows for a relatively high capacitance in a small volume. This oxide has a dielectric constant of 10, which is several times higher than most common polymer insulators. This layer can withstand an electric field strength of the order of 25 megavolts per meter which is significant fraction of that of common polymers. This combination of high capacitance and reasonably high voltage result in high energy density.

2011-3-24 12:20:30

views

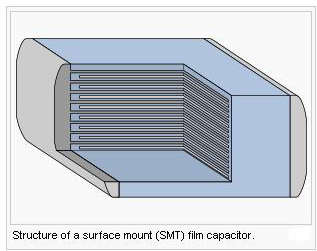

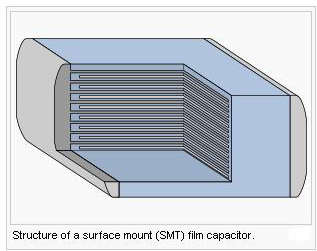

The features of film capacitor are non-inductive construction, self-healing, high reliable and superior performance in high frequency applications. It is applied to filter and noise suppression circuit, pulse logic and timing circuit, DC blocking, by-passing and signal coupling in general communication equipment. The construction of film capacitor includes polyester film dielectric with vacuum-evaporated metal electrodes, radial leads of tinned wire are electrically welded to the contact metal layer on the ends of capacitor winding, epoxy resin coating.

Are you interested in learning more details about Film Capacitors? jb Capacitors manufactures and markets Plastic Film Capacitors, Including Mylar Polyester Film Capacitor, Metallized Polyester Film Capacitor, Box Type Met Polyester Film Capacitor, X2 Metallized Polypropylene Film Capacitor and Metallized Polypropylene Film AC Capacitor Class-X1 etc. Please refer to our website www.jbcapacitors.com for the detailed Film Capacitors.