2018-7-3 16:55:1

views

jb invite you to enjoy the most exciting game FIFA world cup.

jb also share with you that we have very special price promotion for SMD aluminum electrolytic capacitors during FIFA world cup period.

We have wide range offer for you: Long life (10,000 hours), Low impedance / leakage, Bi-polar type etc.

Hot products: JCS 2,000hours 85’C, JCK 1,000~2,000hours 105’C, JCZ 3,000hours 105’C extra low impedance.

Contact us with your inquiry, you will receive unequalled good price from us!

2018-6-12 16:43:16

views

The capacitors market is not stable recently, I believe you have also heard that E-Cap has raised prices in the Chinese market recently. Do you encounter such as trouble?

Are you feel difficult to find high cost performance capacitors?

In fact, jb is the best choice for you.

Plastic film capacitors and Aluminum Electrolytic Capacitors are our strong products.

We have sorted out the Radial Aluminum Electrolytic Capacitor Features list.

Would you like to check your E-CAP inquiry then send to us? I will sure offer you the best price!

| jb THT(Radial)Aluminum Electrolytic Capacitors |

| | Load life | Temperature | Remark |

| JRA | 2000hours | 85C' | General |

| JRB | 2000hours | 105C' | General |

| JRC | 2000hours | 105C' | High Frequency &Low Impedance |

| JRD | 2000~5000hours | 105C' | long life &low impedance |

| JRG | 4000~10000hours | 105C' | long life &Extremely Low Impedance |

| JRW | 2000hours | 105C' | Extra Lower Impedance |

| JRK | 2000hours | 105C' | Height 7mm |

| JRJ | 1000hours | 85C' | Height 7mm |

| JRQ | 1000hours | 105C' | Bi-polarized |

Aluminum-Electrolytic-Capacitor.jpg)

2018-5-15 11:14:42

views

JRA & JRB are very strong series in jb capacitors company

They are suitable for switch power supply and router products, which win the good response from our customers and receive lots of orders every year.

Because of the customers good support for many years, we enhance the our quality constantly and give feedback to market demand.

JRB is the standard type for radial aluminum capacitors, wide temperature range, miniature and large capacity, we provide high quality for sure.

To win your trust, we can offer free samples and competitive price for you!

If you are looking for the alternative power capacitors, please feel free to contact us!

We look forward to our nice beginning with you.

2018-4-17 14:53:57

views

Our jb Capacitors Company produce E-cap since 1980, with high quality, fast delivery time & very good prices.

Many big distributor and manufacutres buy E-cap from us for long time, below is one of our customer’s good feedback. We would like to share to all of you :

We are buying your E-caps since 2009, and so far we have good track record with them.

We are in the high quality custom power supply business. Most of our products are designed for 30 years operating life. As you noticed, our purchasing quantities steadily increased for your E-capacitors, and we plan to do so.

However, the past taught us to be tedious to collect reliability record on many critical items, mainly E-capacitors.

As said, in the coming year, we will increase our purchases from JP Capacitor, since we are very happy with your service, support and response times.

Please check our products link: http://www.jbcapacitors.com/Aluminum-Electrolytic-Capacitors/ and send us more E-cap inquiries. We’re always ready to give full support for you.

From jb Capacitors Company

----Just your best choice

2018-3-13 13:44:57

views

Dear Friends,

Good news for you!

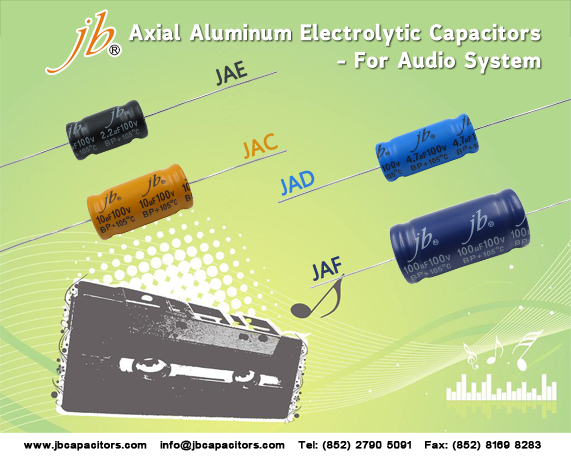

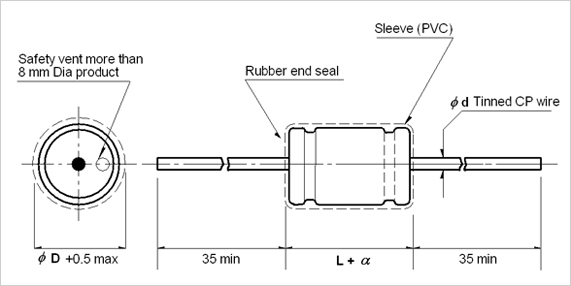

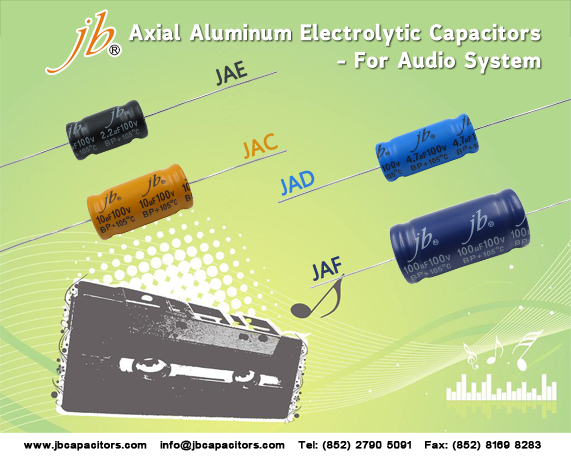

Recently, jb Capacitors Company developed few series of axial aluminum electrolytic capacitors, especially for audio system.

High quality commitment, competitive prices supported during Spring Season. Any interest, please don’t be hesitate to contact our sales for best quotation.

We are ready here to offer you great services.

Email: info@jbcapacitors.com

Feacture:

- Bi-Polarized

- 105”C 1000 hours

- Different low Dissipation Fact MAX 4% at 1KHz/ MAX 5% at 1KHz/ MAX 10% at 1KHz/ or MAX 4% at 120Hz

- High-quality crossover non-polar aluminum electrolytic capacitors

Application:

- Specially produced for Cross-Over Networks with high fidelity audio system

- Product mainly used: Tube Amplifiers, Audio and HiFI Systems, Audio Converters and Dividers (partials), Audio amp, Automotive Electronics Products, speaker and so on

PDF datasheet link:

http://www.jbcapacitors.com/pdf/JAC-Bi-Polarized-Axial-Aluminum-Electrolytic-Capacitors-For-Audio-System.pdf

http://www.jbcapacitors.com/pdf/JAD-Bi-Polarized-Axial-Aluminum-Electrolytic-Capacitors-For-Audio-System.pdf

http://www.jbcapacitors.com/pdf/JAE-Bi-Polarized-Axial-Aluminum-Electrolytic-Capacitors-For-Audio-System.pdf

http://www.jbcapacitors.com/pdf/JAF-Bi-Polarized-Axial-Aluminum-Electrolytic-Capacitors-For-Audio-System.pdf

2018-3-13 11:43:42

views

Today we introduce the Main Methods of Testing E-cap Lifetime.

Usually we have two methods for testing lifetime, please find more detail information as below:

1. Normal testing: (Periodic sampling is conducted every four months)

The environment temperature test: 20 ℃~25 ℃

Relative humidity: 45%-75%

Relative air pressure: 86kpa-106 kpa

Inspection items: High temperature 105 ℃ storage 3000 Hours

High temperature life test the durability: 3000 Hours

For above test, we have exact equipment for testing, after testing, the real test data can prove the product of real lifetime.

2. Destructive testing: (do the regular sampling inspection every 2 months)

Put the capacitors in the oven, the temperature raise 10 degrees (for example: if the capacitors' oringinal temperature is 105 ℃, it needs rise to 115 ℃).

let current go through (should be the capacitor's current), then the capacitors' lifetime will decay half. (it means, 3000 Hours becomes 1500 hours), after testing 63 days, will take out capacitors and see if it can still work or not.

You are kindly to check more E-caps information from our website:

http://www.jbcapacitors.com/Aluminum-Electrolytic-Capacitors/

From jb Capacitors Company

-- Just your best choice

2018-2-7 17:54:33

views

With the Chinese New Year coming, jb launched four new series of audio capacitors.

They are all good quality e-caps, can bring your audio system a great performance.

Now click below series name to check their PDF datasheets!

Hope you will bring us many of new orders in Dog of the year. Happy CNY !

| Series | JAC | JAD | JAE | JAF |

| Items | Performance Characteristics |

| Operating Temperature Range | -40℃~+105℃ |

| Load Life | 1000 hours |

| Capacitance Tolerance | ±10% |

| Leakage Current (μA) | MAX. 0.03CV + 3μA After 5 minutes application of rated working voltage |

| MAX Dissipation Factor | MAX 4% at 1KHz | MAX 5% at 1KHz | MAX 10% at 1KHz | MAX 4% at 120Hz |

| Features | Bi-Polarized |

| Specially produced for Cross-Over Networks with high fidelity audio system |

| High-quality crossover non-polar aluminum electrolytic capacitors |

| Application | Audio Converters and Dividers (partials), Audio amp, Automotive Electronics Products, speaker |

2018-1-16 0:7:3

views

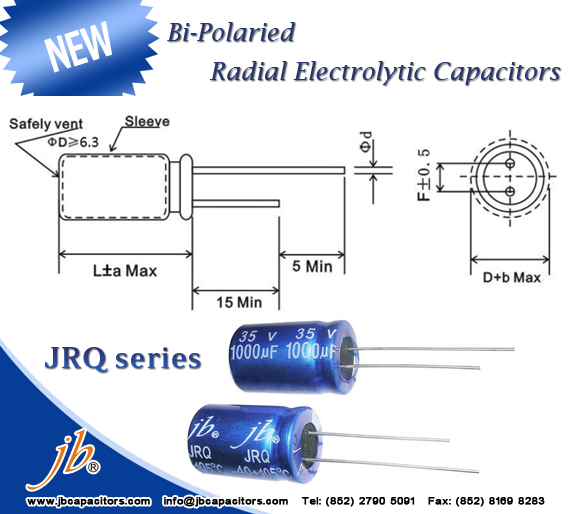

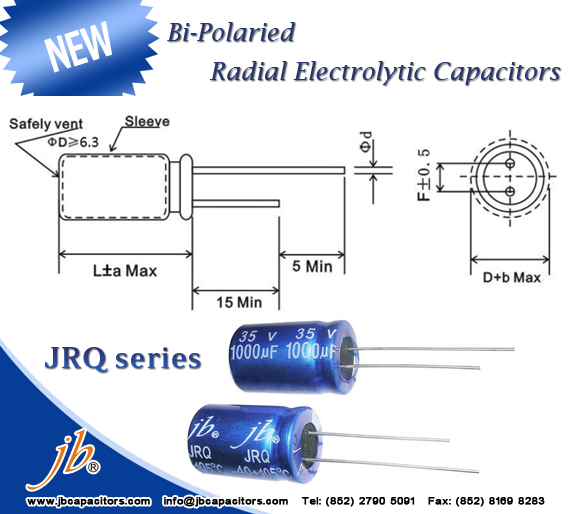

Good news! Recently we released another Radial electrolytic capacitors---JRQ series. The support is very good.

Are you looking for such Bi-Polaried Radial E-cap? Welcome to send us inquiry at once.

JRQ - 1000H at 105C, Bi-Polaried Radial Aluminum Electrolytic Capacitor

* Bi-Polarized

* 105C 1000 hours

* Used in polarity reverse and change circuits

* Operating Temperature Range: -40C~+105C

* Capacitance Tolerance: (25°C, 120Hz) ±20%

* Leakage Current: (μA) I≤0.03CV + 3(μA) (1minute)

PDF datasheet: http://www.jbcapacitors.com/pdf/JRQ-105-Bi-Polaried-Radial-Aluminum-Electrolytic-Capacitors.pdf

From jb Capacitors Company

-------We're just your best choice

2017-11-23 0:14:48

views

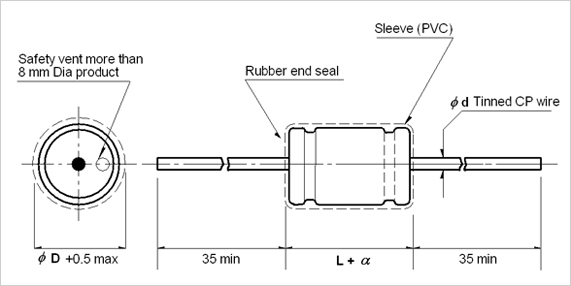

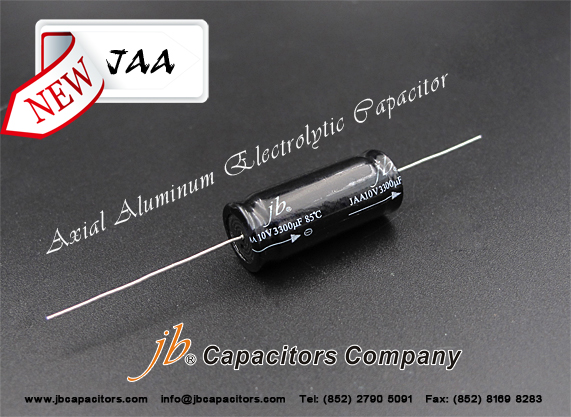

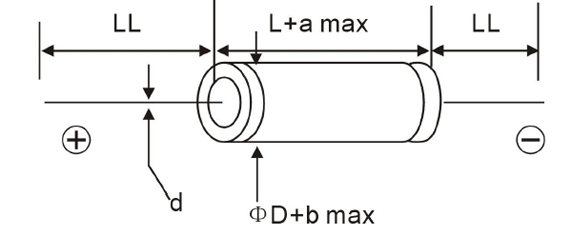

To meet market needs, we released newest Axial lead E-cap--JAA and JAB series, both series are 2000H at 85C. Please find detail difference as below:

JAA - 2000H at 85°C, Axial Aluminum Electrolytic Capacitors (Low Leakage)

• Load life of 2000 hours at 85°C

• Low Leakage Current

• 2 Rubber Types

• For general purpose application

• RoHS Directive Compliant

PDF datasheet: http://www.jbcapacitors.com/pdf/JAA-85-Axial-Aluminum-Electrolytic-Capacitors-Low-Leakage.pdf

JAB - 2000H at 85°C, Axial Aluminum Electrolytic Capacitors

• Load life of 2000 hours at 85°C

• Low Voltage

• 2 Rubber Types

• For general purpose application

• RoHS Directive Compliant

PDF datasheet: http://www.jbcapacitors.com/pdf/JAB-85-Axial-Aluminum-Electrolytic-Capacitors.pdf

JAA, JAB series Drawing:

From jb Capacitors Company

-------We're just your best choice

Aluminum-Electrolytic-Capacitor.jpg)