2016-5-19 0:34:1

views

Серия JRB – это новая серия электролитических конденсаторов в складской программе Компэл от известного производителя JB Capacitors. Эти конденсаторы предназначены для самого массового сегмента потребительской электроники, имеющие базовые параметры рабочего температурного диапазона от -40℃ до +105℃ и времени наработки на отказ в 2000 часов.

Такое соотношение характеристик позволяет предложить производителям электроники хорошее

соотношение цена/надежность. Применение электролитических конденсаторов с базовой

наработкой в 2000 часов позволяет существенно снизить стоимость конечного продукта при

больших производственных объемах. Конденсаторы JRB являются аналогом и отличной

альтернативой таким сериям конденсаторов, как EHR от Hitano, TM от Jamicon, RD от Samwha, SH от Yageo. Основные диапазоны электрических параметров, в рамках которых могут быть выбраны конденсаторы серии JRB представлены ниже:

Рабочий диапазон температур -40℃ ~ +105℃ -25℃ ~ +105℃

Рабочее напряжение 6,3 ~ 100 В 160 ~ 450 В

Номинальная емкость 0,1 ~ 22000 мкФ 0,47 ~ 470 мкФ

Начальный допуск +/- 20%

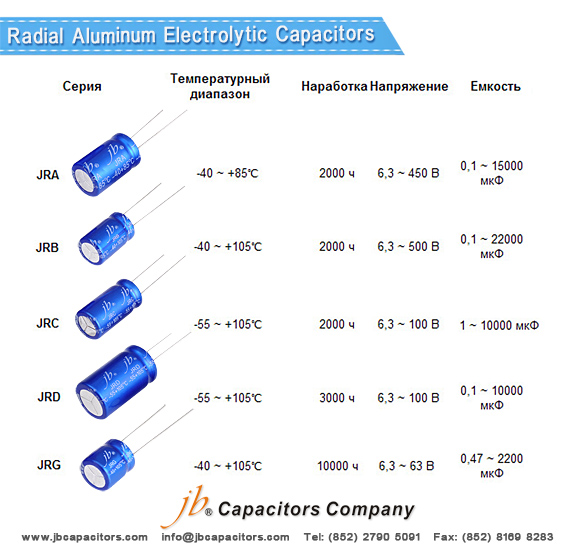

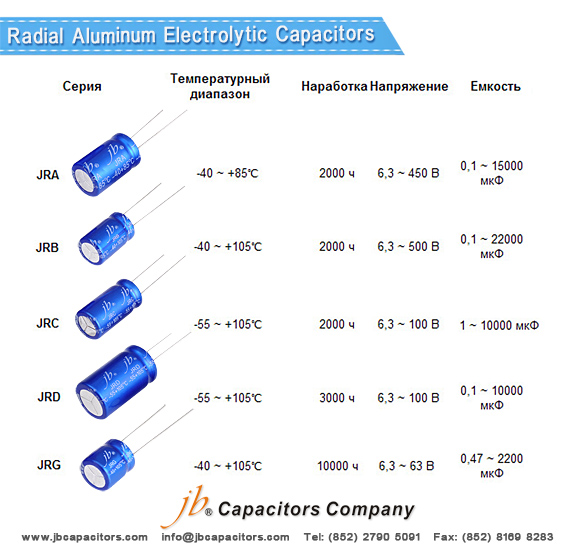

Полная линейка радиальных миниатюрных электролитических конденсаторов производства jb Capacitors состоит из 5 серий и включает в себя решения с наработкой до 10000 часов:

http://www.compel.ru/2016/05/16/jrb-horoshie-kondensatoryi-po-otlichnoy-tsene-ot-jb-capacitors

2016-5-17 0:9:30

views

After updated the RoHS2.0 for radial type aluminum electrolytic capacitors, we updated our certificate for ISO again in March.

And we will update the RoHS2.0 for all film capacitors and SMD type aluminum electrolytic capacitors

soon.

jb capacitors are working more hard to get the best support for our customers, we are looking forward to win more & more market shares together with our customers.

We welcome more win-win cooperations.

2016-5-3 0:57:2

views

The electrolytic capacitor has been in use for many years. Its history can be traced back to the very early days or radio around the time when the first broadcasts of entertainment were being made. At the time, valve wireless sets were very expensive, and they had to run from batteries.

However with the development of the indirectly heated valve or vacuum tube it became possible to use AC mains power.

While it was fine for the heaters to run from an AC supply, the anode supply needed to be rectified and smoothed to prevent mains hum appearing on the audio.

In order to be able to use a capacitor that was not too large Julius Lilienfield who was heavily involved in developing wireless sets for domestic use was able to develop the electrolytic capacitor, allowing a component with sufficiently high capacitance but reasonable size to be used in the wireless sets of the day.

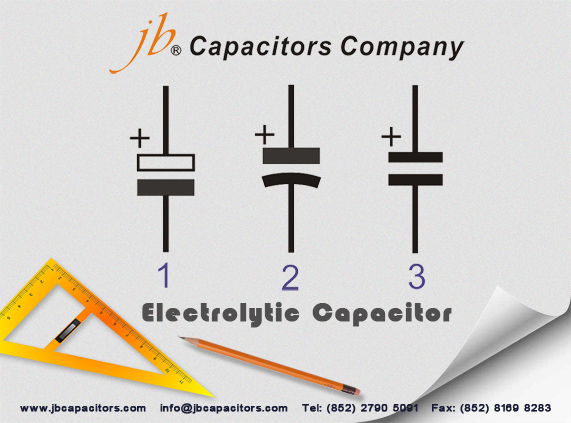

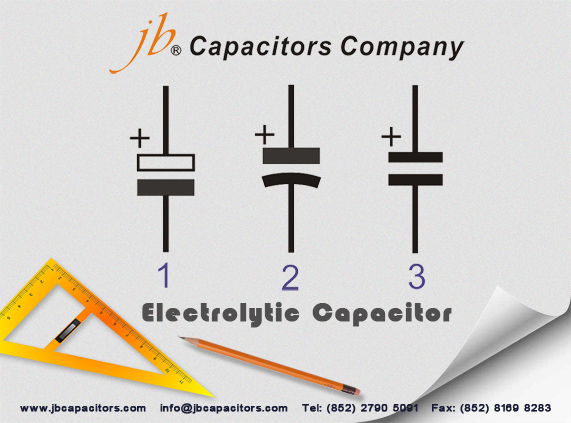

Electrolytic capacitor symbols

The electrolytic capacitor is a form of polarised capacitor. The electrolytic circuit symbol indicates the polarity as it is essential to ensure that the capacitor is fitted into the circuit correctly and is not reverse biased.

Circuit symbols used for polarised capacitors like the electrolytic capacitor

There is a variety of schematic symbols used for electrolytic capacitors. The first one '1' is the version that tends to be used in European circuit diagrams, while '2' is used in many US schematics, and '3' may be seen on some older schematics. Some schematic diagrams do not print the "+" adjacent to the symbol where it is already obvious which plate is which.

2016-3-29 0:35:9

views

An aluminum electrolytic capacitor, usually simply called an electrolytic capacitor (e-cap), is a capacitorwhose anode (+) consists of pure aluminum foil with an etched surface, covered with a uniformly very thin barrier layer of insulating aluminum oxide, which operates as a dielectric.

The electrolyte, which covers the rough surface of the oxide layer, operates as the second electrode, the cathode (-).

E-caps have the largest capacitance values per unit volume compared to the two other main conventional capacitor families, ceramic and plastic film capacitors, but articulately smaller capacitance than similar sized supercapacitors.

Come to us jb Capacitors, a professional manufacturer for film capacitors, and aluminum electrolytic capacitors.

let us provide you the most professional support on technical side, marketing side.

2016-3-7 18:24:56

views

An electrolytic capacitor is a type of capacitor that uses an electrolyte to achieve a larger capacitance than other capacitor types. An electrolyte is a liquid or gel containing a high concentration of ions.

Almost all electrolytic capacitors are polarized, which means that the voltage on the positive terminal must always be greater than the voltage on the negative terminal.

The benefit of large capacitance in electrolytic capacitors comes with several drawbacks as well.

Among these drawbacks are large leakage currents, value tolerances, equivalent series resistance and a limited lifetime.

Electrolytic capacitors can be either wet-electrolyte or solid polymer. They are commonly made of tantalum or aluminum, although other materials may be used.

Super capacitors are a special subtype of electrolytic capacitors, also called double-layer electrolytic capacitors, with capacitances of hundreds and thousands of farads.

This article will be based on aluminum electrolytic capacitors. These have a typical capacitance between 1µF to 47µF and an operating voltage of up to a few hundred volts DC.

Aluminum electrolytic capacitors are found in many applications such as power supplies, computer motherboards and many domestic appliances. Since they are polarized, they may be used only in DC circuits.

Read more information please check our company website: http://www.jbcapacitors.com/Aluminum-Electrolytic-Capacitors/

From jb Capacitors Company sales department

2016-3-2 19:14:44

views

Good news to announce that we updated jb Radial Electrolytic Capacitors RoHS 2.0 report at the early of 2016.

The goods we supply are with RoHS compliant and lead free.

Radial Aluminum Electrolytic Capacitors include below series, other specification available on request.

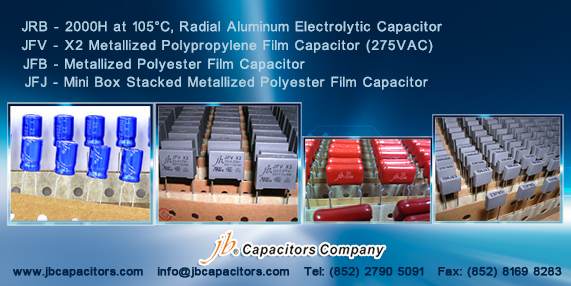

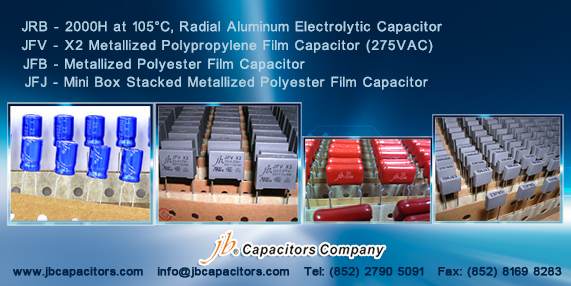

JRA - 2000H at 85°C, Radial Aluminum Electrolytic Capacitors (Hot)

JRB - 2000H at 105°C, Radial Aluminum Electrolytic Capacitors(Hot)

JRC - 2000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRD - 5000H at 105°C, Radial Aluminum Electrolytic Capacitors

JRG - 10000H at 105°C, Radial Aluminum Electrolytic Capacitors

More information please check below link:

http://www.jbcapacitors.com/pdf/jb-Radial-Electrolytic-Capacitors-Leaflet.pdf

2016-2-17 22:25:31

views

| Load Life | 2000h at 85C | 3000h at 85C | 2000h at 105C |

| jb | JNC | JNC | JNE |

| Epcos | B41231 | B43510/

B43520 | B43511/

B43521 | B41252 | B43504 | B43515/

B43525 |

| NipponChemi-Con | SMQ | SMH | SMM | KMQ, KMH | KMT | KMR |

| Nichicon | LS | LG | / | GG | GL | AK,AQ |

| Panasonic | TS-UQ | T-UP | / | TS-MD | TS-HC | / |

| Samwha | HC | AM | / | HE | / | / |

| Kendeil | K26 | / | / | K25 | / | / |

| Yageo | LH | / | / | LG | / | / |

| DAEWOO | FHS | FHX | FHT | FUH | / | / |

More information please check below link:

http://www.jbcapacitors.com/Aluminum-Electrolytic-Capacitors/JNC-2000H-at-85-Snap-in-Aluminum-Electrolytic-Capacitor.html

http://www.jbcapacitors.com/Aluminum-Electrolytic-Capacitors/JNE-Snap-in-105-Miniaturized-Aluminum-Electrolytic-Capacitor.html

2016-2-15 20:19:19

views

jb Capacitors Company return to normal work after CNY holiday already, please feel free to contact our sales for your any requests or orders.

We are ready to give you the fullest support, and hope we can get more win-win business in this new year 2016.

In Febuary, we have below special offer for SMD type aluminum electrolytic capacitors, prices support are much more better than normal, please kindly send us your RFQs for quote, thanks.

JCS- SMD aluminum electrolytic capacitors, 2000hours at 85C'

JCK- SMD aluminum electrolytic capacitors, 1000~2000hours at 105C'

JCC - 2000H at 85°C, Low Leakage SMD Aluminum Electrolytic Capacitor

JCD - 2000H at 105°C, Low Impedance SMD Aluminum Electrolytic Capacitor

JCE - 3000H at 105°C, Long Life Assurance SMD Aluminum Electrolytic Capacitor

JCL - 5000H at 105°C SMD Aluminum Electrolytic Capacitor

JCN - 1000H at 85°C, Bi-polar SMD Aluminum Electrolytic Capacitor

JCZ - 3000H at 105°C, Extra Lower Impedance SMD Aluminum Electrolytic Capacitor

2016-1-19 0:57:40

views

jb Capacitors Company Offer Ammo Package for Radial Aluminum electrolytic capacitors, MKT MKP film capacitors, make your PCB Assembly more easy, automative assemby, you will save more labor cost. :)

Welcome to send me your request!

More information please check below link: http://www.jbcapacitors.com/products.html

2016-1-13 19:52:50

views

We would like to share the most common Radial Aluminum Electrolytic to our customers.

Please find below table for reference.

| 1000uF 10V +/-20% D*L: 8*14mm P: 3.5mm 1000H at 105'C Bulk RoHS |

| 1000uF 16V +/-20% D*L: 10*16mm P: 5mm 2000H at 105'C Bulk RoHS |

| 1000uF 25V +/-20% D*L: 10*20mm P: 5mm 2000H at 105'C Bulk RoHS |

| 1000uF 35V +/-20% D*L: 13*20mm P: 5mm 2000H at 105'C Bulk RoHS |

| 100uF 160V +/-20% D*L: 13*25mm P: 5mm 2000H at 105'C Bulk RoHS |

| 2200uF 16V +/-20% D*L: 10*20mm P: 5mm 2000H at 105'C Bulk RoHS |

| 2200uF 25V +/-20% D*L: 13*25mm P: 5mm 2000H at 105'C Bulk RoHS |

| 2200uF 35V +/-20% D*L: 16*25mm P: 7.5mm 2000H at 105'C Bulk RoHS |

| 220uF 16V +/-20% D*L: 6.3*11mm P: 2.5mm 1000H at 105'C Bulk RoHS |

| 220uF 25V +/-20% D*L: 8*11.5mm P: 3.5mm 1000H at 105'C Bulk RoHS |

| 220uF 35V +/-20% D*L: 8*11.5mm P: 3.5mm 1000H at 105'C Bulk RoHS |

| 3300uF 50V +/-20% D*L: 18*40mm P: 7.5mm 2000H at 105'C Bulk RoHS |

| 330uF 25V +/-20% D*L: 8*11.5mm P: 3.5mm 1000H at 105'C Bulk RoHS |

| 470uF 16V +/-20% D*L: 8*11.5mm P: 3.5mm 1000H at 105'C Bulk RoHS |

| 470uF 25V +/-20% D*L: 8*16mm P: 3.5mm 1000H at 105'C Bulk RoHS |

| 470uF 35V +/-20% D*L: 10*16mm P: 5mm 2000H at 105'C Bulk RoHS |

| 47uF 160V +/-20% D*L: 10*20mm P: 5mm 2000H at 105'C Bulk RoHS |

| 47uF 63V +/-20% D*L: 6.3*11mm P: 2.5mm 1000H at 105'C Bulk RoHS

|

More information please check below link:

http://www.jbcapacitors.com/Aluminum-Electrolytic-Capacitors/JRB-105-Radial-Aluminum-Electrolytic-Capacitors.html