Introduction to Aluminum Electrolytic Capacitors - Part 1

[1] How Capacitors Work

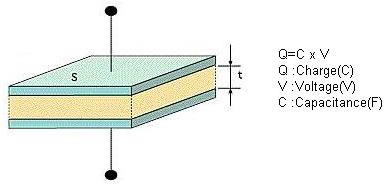

Below picture shows the basic concepts of how capacitors function.

A dielectric material is layered between two metal electrodes, and an electrical charge proportional to the voltage is stored in the capacitor when a voltage is applied across the electrodes.

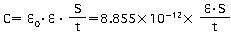

"C" is the capacitance of the capacitor. The capacitance is calculated using the equation shown below as a function of the surface area of the electrodes (S), the distance between the electrodes (t), and the dielectric constant of the dielectric (  ).

).

In the formula above, 0 represents the permittivity of free space (8.85 x 10-12F/m)

A larger capacitance can be obtained by either increasing the dielectric constant, increasing the electrode surface area (S), or by decreasing the distance between the electrodes(t).

The dielectric constant of an aluminum oxide layer averages between 7 and 8. The most frequent dielectric constants of dielectrics used in capacitors are listed in below table.

The effective surface area of aluminum electrolytic capacitors can be increased by as much as 120 times. By roughening the surface of the high-purity aluminum foil, the process makes it possible to produce capacitances far larger than those of other types of capacitors.

| Dielectric Material | Dielectric Constant | Dielectric Material | Dielectric Constant |

| Aluminum oxide thin film | 7 - 8 | Porcelain (ceramic) | 10 - 120 |

| Mylar | 3.2 | Polyethylene | 2.5 |

| Mica | 6 - 8 | Tantalum oxide film | 10 - 20 |

Please note that capacitors are typically described in terms of the primary dielectric material. A few examples are "aluminum electrolytic capacitor" or "tantalum capacitor."

0 Comment so far

Leave a reply