jb Structure of Aluminium Electrolytic Capacitors

Basic construction:

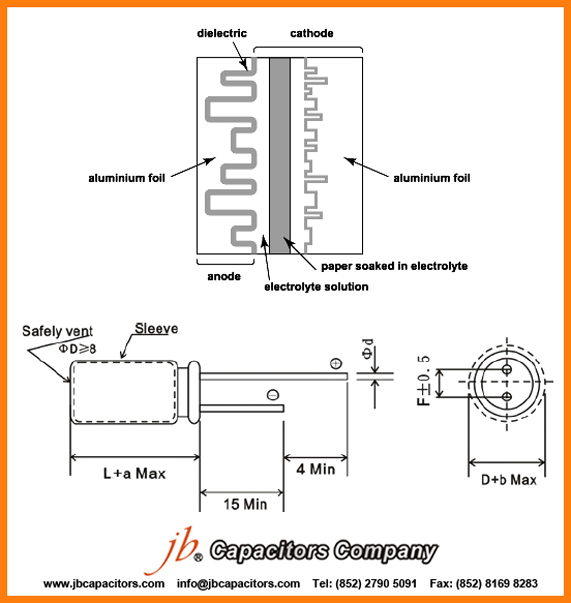

1, Two pieces of foils interleaved with an absorbent paper build up the key element of an Aluminium Electrolytic Capacitor, and all these materials should be wound tightly into a cylinder shape

2, The positive foil, or the anode foil are all made from pure aluminium foil. The aluminium oxide dielectric has been formed electrolytically on the surface..

3, The foil has been etched to make the effective surface area more larger, and the area of the anode is usually 30–100 times larger than the plan area of the foil.

Figure: How dielectric structure works in an Aluminium Electrolytic Capacitor ?

4, The other plate is a combination of high-absorption paper impregnated with an electrolyte, in contact with a cathode foil.

5, The electrolyte is there to make good contact with the anode, by permeating its etched structure, and also to repair any flaws in the oxide layer when the capacitor is polarised.

6, The function of the aluminium cathode foil is to reduce the series resistance of the capacitor by making contact with the paper over a wide area.

We welcome you to order our jb Aluminium Electrolytic Capacitors and anatomy it, if you want to have a more clear understanding of them. Do it yourself will be more fun and meaningful.